The Royal Mint Unveils Sustainable Gold Recovery Factory in South Wales

09 August, 2024

Fintech Wales Member, The Royal Mint, Takes Major Step in Sustainable Practices

In an impressive leap towards sustainability, The Royal Mint, a proud member of Fintech Wales, has unveiled a pioneering factory designed to process up to 4,000 tonnes of printed circuit boards (PCBs) from e-waste annually. This state-of-the-art facility will significantly reduce the reliance on traditional gold mining and promote more sustainable industry practices.

Revolutionizing Gold Recovery

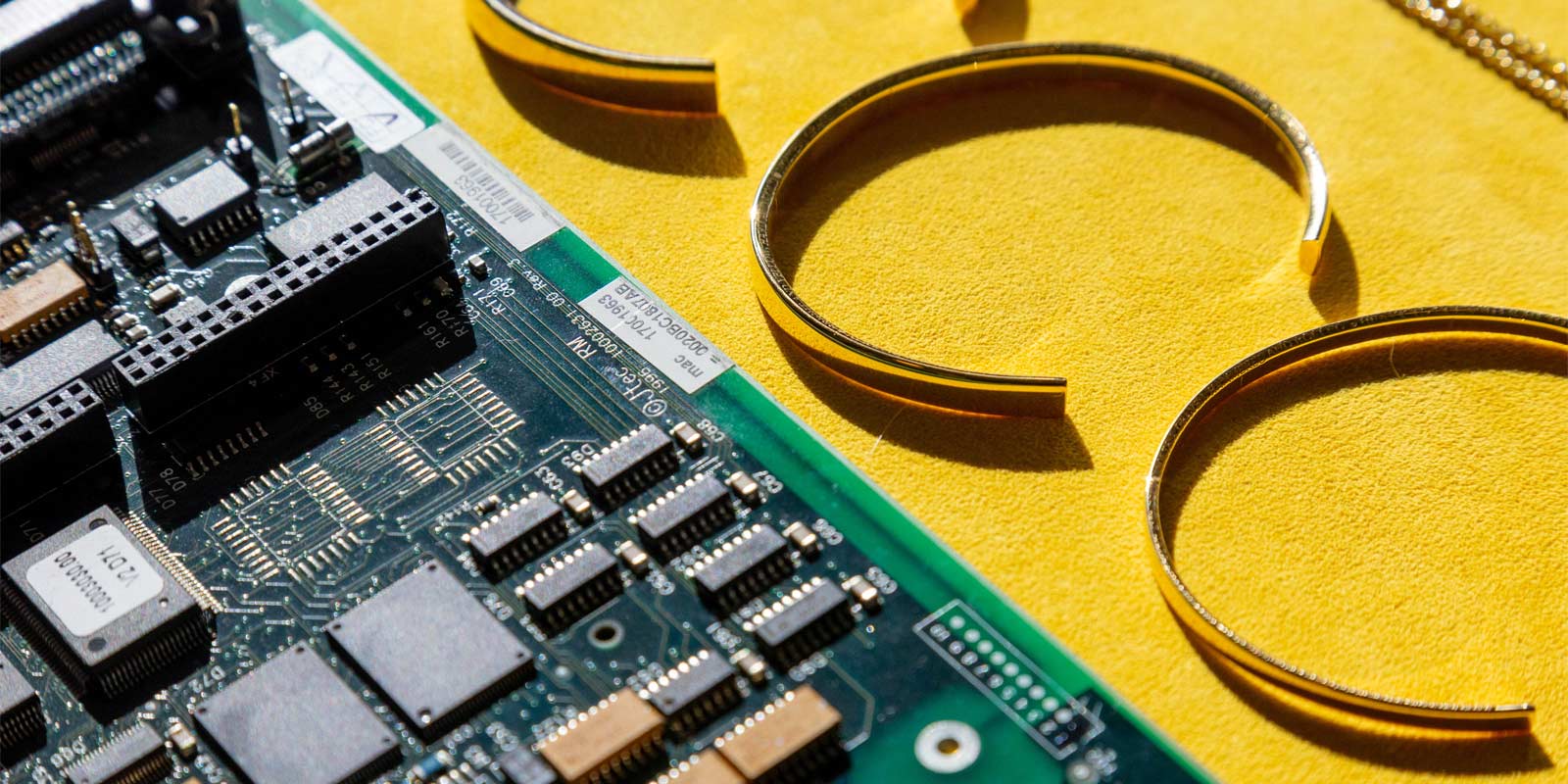

Located at The Royal Mint’s site in South Wales, the 3,700-square-meter factory employs world-first patented chemistry from Canadian clean tech company Excir. This innovative technology extracts high-purity gold from PCBs found in everyday items like TVs, laptops, and mobile phones within minutes, operating at room temperature to enhance energy efficiency and cost-effectiveness.

This facility marks the first industrial-scale application of this technology, transitioning from laboratory research to a full-fledged industrial process. The recovered gold, boasting a purity of 999.9, is already being utilized in the luxury jewellery collection, 886 by The Royal Mint.

Addressing the E-Waste Challenge

The United Nations’ Global E-waste Monitor reports a staggering increase in global e-waste, which is growing by 2.6 million tonnes annually. In 2022 alone, a record 62 million tonnes of e-waste was generated, up 82% from 2010. The new factory provides a sustainable solution to this environmental challenge, ensuring valuable finite resources are recovered, and other materials are appropriately processed for future use.

Leadership in Sustainable Precious Metals

Anne Jessopp, Chief Executive at The Royal Mint, highlighted the significance of this new venture: “The Royal Mint is transforming for the future, and the opening of our Precious Metals Recovery factory marks a pivotal step in our journey. We are not only preserving finite precious metals for future generations, but we are also preserving the expert craftsmanship The Royal Mint is famous for by creating new jobs and reskilling opportunities for our employees. We have ambitious plans, and I am proud that we are safeguarding The Royal Mint for another 1,100 years.”

Sean Millard, Chief Growth Officer at The Royal Mint, echoed this sentiment, emphasizing the factory’s role in their sustainability efforts: “The factory underpins our commitment to using sustainable precious metals and providing a new source of high quality, recovered gold. It allows us to reduce our reliance on mined materials and is another example of how we’re working to decarbonize our operations. Our commitment to growth, innovation, and circular economy principles shapes an exciting and more sustainable future for The Royal Mint, our people, and our communities.”

A Catalyst for Change

The decline of cash use globally has been a catalyst for change at The Royal Mint, fostering innovation and diversification. Earlier this year, The Royal Mint announced the closure of its Overseas Currency division, with all 230 staff offered roles in new and expanding business areas, including the Precious Metals Recovery factory, thereby sustaining manufacturing roles for the future.

Learn More

For details on 886 by The Royal Mint E-Waste Gold, visit Sustainability – 886 Royal Mint.

This development underscores The Royal Mint’s dedication to sustainability and innovation, ensuring its legacy continues for centuries to come. Stay tuned to Fintech Wales for more updates on groundbreaking initiatives by our members.